Adopting model-based engineering methodologies

is a foundational step to enable digital transformation

Selecting an experienced partner like Belcan to help you implement sustainable organization-wide change can be the difference between making that step—or falling behind.

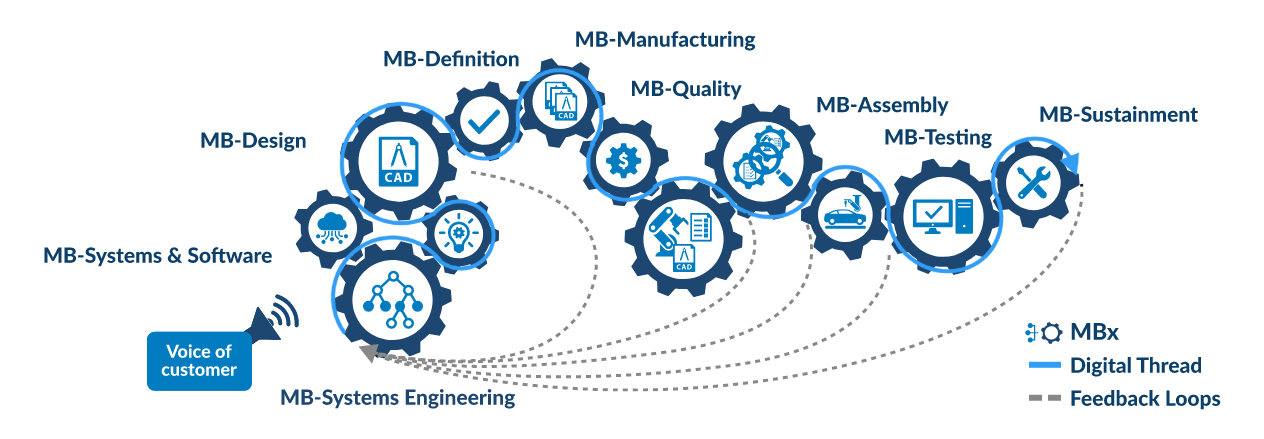

Your organization can become more agile, efficient, and responsive to changing market demands when you equip stakeholders with the tools to use trusted and authoritative digital models throughout the product lifecycle, replacing document-centric artifacts and error-prone workflows. This translates to significant improvements in quality and efficiency — resulting in reduced costs.

A model-based enterprise will create and share digital data artifacts across all phases of a product lifecycle, including product development, planning, sourcing, building, operating, and maintaining.

Digital Twin

Digital twins can simulate the behavior of physical assets, systems, and processes. They enable organizations to reduce risk and cost by correcting issues before they occur, improve performance through optimization, and enhance decision making with real-time insights and data.

Partner with a leader in engineering excellence to bring your digital transformation to life.

Belcan Digital Engineering Solutions provides tailored digital engineering and systems integration solutions focused on solving complex problems across the product lifecycle—and across industry verticals.

Strategy

A successful digital transformation requires a clear vision, strong leadership, trusted data, new technology adoption, empowered teams, customer centricity, and agile processes. By focusing on these critical elements, Belcan Digital Engineering Solutions can help your organization successfully navigate the challenges of digital transformation and realize the benefits of model-based engineering.

Discovery & Deployment

Preparing your organization to create trusted models and readying consumers to leverage model-based artifacts are essential prerequisites to deployment.

Belcan Digital Engineering Solutions anticipates potential roadblocks, delivering comprehensive and agile solutions that minimize deployment risk.

Belcan supports the full range of deployments—from exploratory pilots through scaled program-wide implementations. The people, process, and tool aspects of transformation are supported through role-based training, process standard documentation, software evaluation, and implementation.

Expansion and Maintenance

In a rapidly evolving digital landscape, living roadmaps and a continuous improvement mindset are essential. Belcan cultivates that mindset internally with active participation in industry standard organizations, presentations at key conferences, partnerships with best-in-class software providers, and a commitment to thought leadership efforts that help us maintain digital currency.

Why Partner with Belcan on your Digital Journey?

We Are Demonstrated Implementors

The model-based enterprise experts on Belcan’s Digital Engineering Solutions lead team deliver real-world implementation experience to help you roadmap your digital vision, avoid strategic pitfalls, and accelerate realization of your goals.

Industry Involvement

ASME Y14 Standards, INCOSE, DMSC QIF/Characteristic Working Group, DEDMWG, Aerospace Industries Association, CCSU Industry Advisory Board

Certifications

Aerospace Program Management, Agile Product Owner, Composite Design, GD&T Senior Level Certification, OMG Certified Systems Modeling Professional

Software & Tools

We are tool-agnostic and work confidently across a wide spectrum of systems and software commonly in use on the market.

We Bridge Strategy & Execution

Belcan Digital Engineering Solutions is your trusted partner to bridge strategy and execution to achieve your digital vision.

No matter where your organization stands in the digital transformation process, Belcan’s Digital Engineering Solutions lead team will meet you where you are. Our experts will customize a solution across the enterprise and supply chain that helps your organization reach its goals—and grow beyond them.

We Deliver Measurable Impact

Everything we do is geared towards setting our customers up for long-term success on their digital journey. Our Digital Engineering Solutions team leverages a time-tested combination of strategic expertise and engineering support to produce high-quality, impactful results.

Belcan Modern Slavery Policy

Site design and development by bfw Advertising